Conductive Yarns for E-Textile Sensors Market to Reach USD 1.4 billion by 2036, Driven by Manufacturing-Scale Adoption

Market grows at 8.4% CAGR as durable, washable conductive yarns enable scalable smart garment sensor integration worldwide.

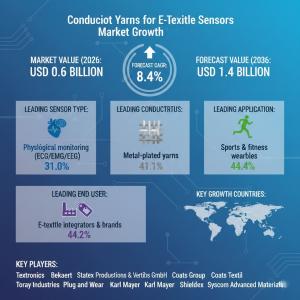

NEWARK, DE, UNITED STATES, January 23, 2026 /EINPresswire.com/ -- The conductive yarns for e-textile sensors market is forecasted to grow from an estimated USD 0.6 billion in 2026 to USD 1.4 billion by 2036, expanding at a robust compound annual growth rate (CAGR) of 8.4%, according to the latest analysis by Future Market Insights (FMI). This growth is driven predominantly by manufacturing-led adoption focused on performance repeatability, textile durability, and integration stability rather than novelty-led pilots.

Market Overview: Meeting Industrial and Consumer Demands Through Reliable Performance

Conductive yarns, integral to the advancement of e-textile sensors embedded in smart garments, are transitioning from prototype materials to standardized, repeat-order components. This shift is fueled by increasing demand for durable, washable, and consistent yarns that maintain stable electrical properties over extended wear cycles. The market growth reflects a paradigm change toward scalable manufacturing and risk-managed procurement strategies, favoring suppliers that demonstrate tight tolerance control, batch consistency, and robust integration capabilities across diverse textile platforms.

Request For Sample Report | Customize Report |purchase Full Report - https://www.futuremarketinsights.com/reports/sample/rep-gb-31747

Key Market Insights and Trends

• Market Size & Growth: Valued at USD 0.6 billion in 2026, the market is projected to more than double to USD 1.4 billion by 2036, with an 8.4% CAGR driven by sustained adoption in sports, fitness, healthcare, and industrial applications.

• Leading Applications and Sensor Types: Sports and fitness wearables dominate, accounting for 44.4% of the market, due to the need for consistent sensor performance under conditions of repeated washing and movement. Physiological monitoring sensors such as ECG, EMG, and EEG hold a 31.0% market share, reflecting stringent requirements for signal stability and accuracy.

• Preferred Conductive Apparatus: Metal-plated yarns lead with a 41.1% share, balancing conductivity and manufacturing familiarity. Their predictable electrical behavior and compatibility with automated textile processes reduce calibration drift and enhance integration efficiency.

• End User Landscape: E-textile integrators and brands represent 44.2% of the market, playing a critical role in defining integration standards, performance acceptance, and supplier selection across multiple garment programs.

Regional Dynamics: USA Leads With Strong Adoption, Followed by Europe and Asia

The United States leads market expansion with an 11.0% CAGR, propelled by rapid uptake in sports and fitness wearables and robust health-monitoring initiatives. The UK follows closely at 10.0%, with growth fueled by innovation in wearable sports technology and streamlined procurement practices.

Germany sustains a 9.9% CAGR, supported by its engineering-focused technical textile industry and integration ecosystems emphasizing performance validation. South Korea’s 9.8% CAGR benefits from a sophisticated electronics ecosystem facilitating manufacturing scale and interface standardization. Japan, while growing more measuredly at 8.9%, maintains rigorous validation and reliability standards that underpin stable procurement cycles.

Challenges and Opportunities in Market Scaling

Despite strong interest and innovation in smart wearables, integration variability across textile manufacturing processes, finishing chemistries, and sensor module placements remains a barrier to faster market adoption. Standardization of resistance targets, connector methods, and module interfaces are critical to reducing field variability and enhancing repeat procurement confidence.

Automation in manufacturing—encompassing stitching, embroidery, and lamination—emerges as a competitive differentiator. Suppliers enabling consistent lot performance and supporting automated integration workflows are poised to capture larger shares of multi-factory production contracts.

Competitive Landscape and Industry Players

Competition is centered around achieving electrical consistency, textile durability, and superior integration support. Market leaders such as Textronics, Bekaert, Statex Produktions & Vertriebs GmbH, Coats Group, Toray Industries, Plug and Wear, Schoeller Textil, Karl Mayer, Shieldex, and Syscom Advanced Materials distinguish themselves by delivering tightly controlled resistance ranges, post-wash performance reliability, and application engineering assistance during production scale-up.

These companies also provide comprehensive documentation to simplify qualification processes, thereby facilitating global production and repeat ordering across diverse manufacturing partners.

Conclusion

The conductive yarns for e-textile sensors market is transitioning from early-stage experimentation to a mature, manufacturing-driven ecosystem. Growth is anchored by increasing demand for standardized, durable, and scalable yarn formats that underpin multi-sensor platforms across health, fitness, industrial, and consumer applications.

Manufacturers and integrators that prioritize stable electrical performance, wash durability, and automated integration will drive the next wave of commercialization. With the market poised to more than double over the next decade, stakeholders in textile manufacturing, wearable technology, and smart health monitoring are advised to focus on repeatable quality, integration efficiency, and cross-industry collaboration to capture emerging opportunities.

Browse Related Insights

Nonwoven Fabrics Market: https://www.futuremarketinsights.com/reports/nonwoven-fabrics-market

Laser Safety Cloths Market: https://www.futuremarketinsights.com/reports/laser-safety-cloths-market

Chef Apparel Market: https://www.futuremarketinsights.com/reports/chef-apparel-market

Demand for Glass Fiber in EU: https://www.futuremarketinsights.com/reports/demand-for-glass-fiber-in-eu

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.