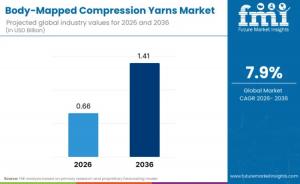

Body-Mapped Compression Yarns Market to Grow at 7.9% CAGR Through 2036 on Precision Apparel Demand

The body-mapped compression yarns market to reach USD 1.41 billion by 2036, driven by precision compression, seamless knitting, and durability-led compliance.

NEWARK, DE, UNITED STATES, February 5, 2026 /EINPresswire.com/ -- Global Market Outlook: Precision, Not Volume, Defines Growth

The Body-Mapped Compression Yarns Market is transitioning from commodity stretch sourcing to engineered performance systems. Valued at USD 0.66 billion in 2026, the market is forecast to reach USD 1.41 billion by 2036, expanding at a 7.9% CAGR, according to Future Market Insights (FMI).

Demand is no longer driven by higher garment volumes alone. Instead, it is shaped by how accurately compression pressure can be engineered, maintained, and validated over repeated wear and laundering cycles. Brands and medical channels are prioritizing yarn systems that deliver stable pressure gradients in seamless and body-mapped garments, minimizing rework, warranty exposure, and inventory risk.

Request For Sample Report | Customize Report | Purchase Full Report–

https://www.futuremarketinsights.com/reports/sample/rep-gb-31808

Key Forces Accelerating Market Expansion

Two evidence-backed capability shifts are accelerating value growth faster than conventional stretch yarn demand:

- Bio-integrated elastomer supply is evolving from a sustainability feature into a procurement requirement as brands prepare for durability disclosure and product passport regulations.

- Digital seamless knitting platforms now enable complex zonal compression at commercial scale, redefining how yarn demand is specified and executed.

Regulatory pressure reinforces this trajectory. The EU’s Ecodesign for Sustainable Products Regulation, effective from July 2024, introduces binding durability and data disclosure pathways. This elevates traceable, low-volatility yarn systems from optional to contract-critical inputs for Europe-facing apparel programs.

Technology and Vertical Integration Reshape Supplier Strategies

Upstream material strategies highlight how compression yarns are becoming risk-managed inputs rather than interchangeable elastics. Hyosung’s bio-BDO and bio-spandex integration exemplifies this shift. Stable, vertically integrated elastomer pathways reduce modulus drift, which is critical in high-power stretch applications where minor elasticity changes can alter garment pressure outcomes.

Machinery-led influence is also rising. Seamless knitting platforms allow stitch-level compression control, making yarn selection inseparable from machine capability. This has shortened sampling cycles and improved yield consistency for zoned compression garments produced in shorter, demand-responsive runs.

Market Evolution: From Elasticity to Compression Architecture

FMI analysis indicates the market is evolving toward software-defined compression architectures, where yarn choice, stitch density, and recovery behavior are engineered as a unified system. Analysts expect:

- Reduced reliance on commodity elastics

- Higher demand for recovery-stable yarns compatible with seamless platforms

- Greater emphasis on pressure retention data over aesthetic tightness

This evolution aligns compression yarn demand more closely with manufacturing execution and compliance readiness than with apparel category cycles.

Segmentation Highlights: Where Value Concentrates

By Compression Profile

Graduated compression yarns account for the largest share of demand due to their balance of performance credibility and manufacturing simplicity.

They enable brands to communicate functional benefits without fully bespoke zoning libraries.

By Application

Sports and performance wear represents the leading application segment, accounting for over 40% of demand.

Compression is evaluated based on comfort under motion, fatigue reduction, and moisture management rather than static tightness.

By Yarn Type

Texture and air-covered yarns dominate selection due to superior hand feel, breathability, and skin-contact comfort.

Regional Outlook: Execution Capability Drives Growth

- China (9.4% CAGR) leads growth through manufacturing differentiation, supported by dense clusters of spandex producers and seamless knitting facilities.

- United States (8.9% CAGR) demand is anchored in medical-adjacent and recovery wear, where pressure decay poses clinical and liability risks.

- Germany (7.8% CAGR) acts as a validation hub, emphasizing auditable pressure retention, traceability, and reproducibility.

- United Kingdom (7.9% CAGR) adoption is driven by seamless shapewear and comfort-led compression for inclusive sizing.

- Japan (6.7% CAGR) prioritizes precision and refinement, adopting compression only when it integrates invisibly into fabric structure.

Competitive Landscape: Risk Absorption Defines Advantage

Competitive positioning is increasingly shaped by where suppliers absorb operational and compliance risk:

- Material stability leaders focus on feedstock insulation and long-term recovery consistency.

- Manufacturing determinism players leverage seamless machine control to lock compression geometry early.

- Functional integrators embed compression alongside moisture, UV, and comfort properties to protect margins and reduce downstream complexity.

Market Definition

The body-mapped compression yarns market comprises engineered yarn systems designed to deliver predictable, location-specific compression within knitted and seamless garments. Unlike generic stretch yarns, these systems are specified for pressure stability, elastic recovery, and long service life across repeated motion and laundering cycles.

Commercial adoption spans sports and performance wear, shapewear, and medical garments where compression outcomes directly influence comfort, efficacy, and compliance.

Get data that aligns with your strategic priorities — ask for report customization today:

https://www.futuremarketinsights.com/customization-available/rep-gb-31808

Related Reports

Polysulfide Market- https://www.futuremarketinsights.com/reports/polysulfide-market

Joint Compound Market- https://www.futuremarketinsights.com/reports/joint-compound-market

Specialty Silica Market- https://www.futuremarketinsights.com/reports/specialty-silica-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

Why FMI: https://www.futuremarketinsights.com/why-fmi

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.